Spark Plugs

Get sustained performance and longevity with Bosch Iridium, Nickel and Platinum Spark Plugs designed for Cars and Bikes

Decode Your Bosch Spark Plug Code

Every Bosch spark plug tells a story written in precision.

Its unique code is a powerful combination of letters and numbers that defines everything from fitment and heat performance to electrode design and materials

Each character reveals a specific engineering detail.

Together, they ensure the perfect spark for your engine.

Bosch Spark Plug History – Technical Milestones

Videos

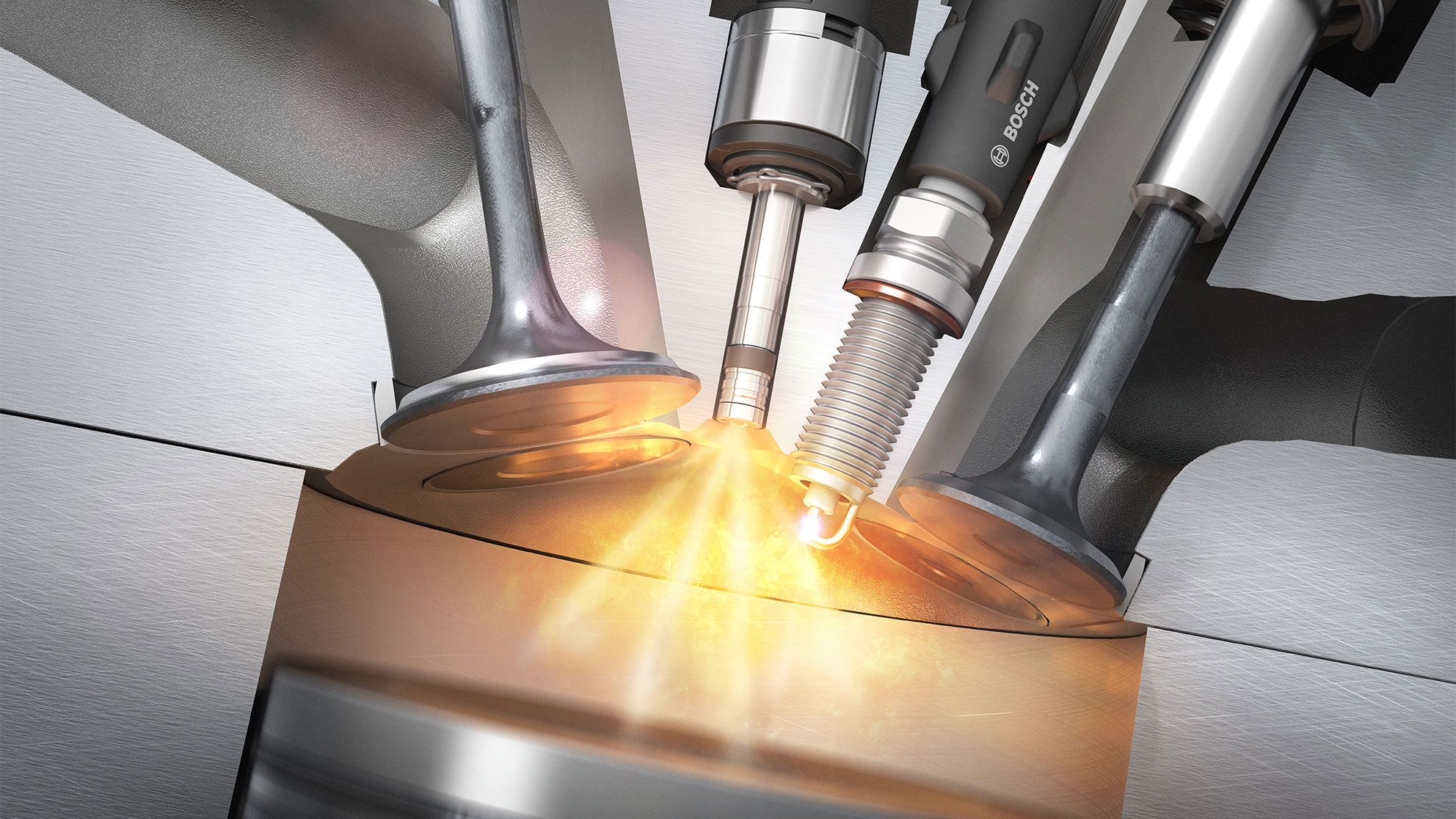

Heroes under the hood: Bosch spark plugs

Bosch Spark Plugs: Nickel versus Precious Metal

Downloads

|

Catalogue: Spark plugs

|